For example, triaxial accelerometers measure acceleration in three orthogonal directions (that is, three axes). There are also different types of accelerometers, with varying strengths and recommended applications. Accelerometers produce electrical signals proportional to forces that they are measuring. Dynamic forces, such as vibration, are those applied to objects at varying rates.

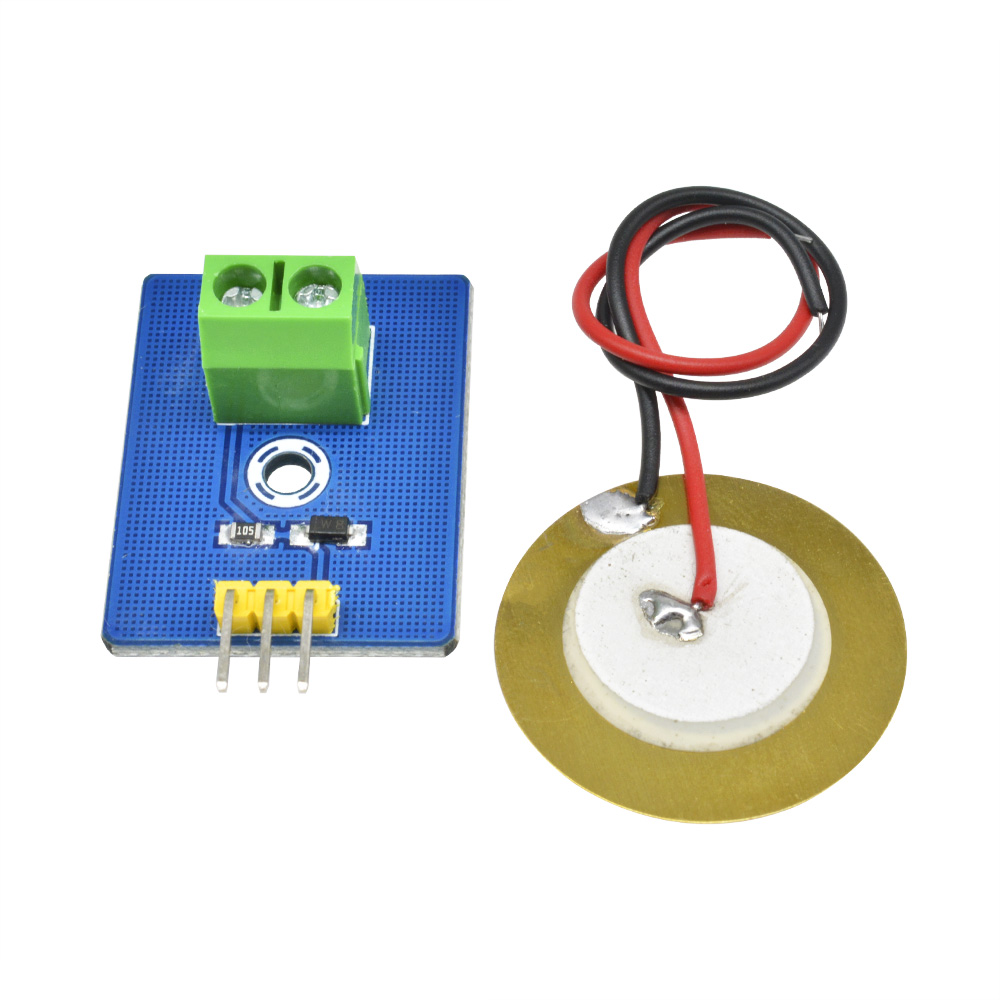

Static forces, such as gravity, are constantly acting on objects. An accelerometer measures the acceleration forces acting on an object. Accelerometer Vibration SensorsĪccelerometer vibration sensors are another extremely common type of vibration sensor. For example, they can handle a wide range of temperatures.Īnd while piezo vibration sensors’ sensitivity and small size make them ideal for many industrial applications, one drawback is that they can consume more power than some other types of vibration sensors. Those qualities have made an extremely popular choice for industrial vibration sensors. Piezo vibration sensors capture highly accurate and dependable data, and they are robust and rugged enough to withstand harsh environments. The applied force generates an electrical charge, which is then converted into measurable electrical signals. Piezoelectric vibration sensors (also called piezo vibration sensors) capture changes in physical parameters or forces. There are multiple types of vibration sensors available, with options for many applications and budgets. That vibration monitoring data can be analyzed and trended to help maintenance teams plan and prioritize their work. Different types of vibration sensors mounted on motors and other equipment can detect when and how a machine’s vibration changes. Every machine has its own vibration signature, and changes in a machine’s vibration can indicate potential faults.

0 kommentar(er)

0 kommentar(er)